China Seamless Ss Tubing Manufacturers - High Quality Cold extrusion sleeve – Hengye

China Seamless Ss Tubing Manufacturers - High Quality Cold extrusion sleeve – Hengye Detail:

Main Features

Its stability is not affected by the chemical composition of steel bars, human factors, climate, electricity and many other factors. Green environmental protection, no pollution, meet the requirements of environmental protection, no open fire operation and construction safe and reliable. Applicable to a wide range of applications, suitable for all kinds of orientation and the same, reducing steel bar connection. Stable and reliable quality, easy to use, simple operation, fast construction speed.

The operation process of cold extrusion connecting sleeve is introduced

1. fixed professional operation staff, and passed the assessment, with the certificate.

2. In order to improve the efficiency, in the processing area, the steel sleeve is connected with the steel bar to complete half of the extrusion head, and the other half of the extrusion head is extruded on site, but the semi-finished product should be set up and placed to prevent the pollution in the extrusion cylinder.

3. In the extrusion work, it is advisable to start from the indentation mark in the middle of the joint to both ends.

4, cold extrusion connecting sleeve should meet the specifications of steel bar, with a large generation of small method is not all desirable, depending on the situation, for example: when the diameter of steel bar changes, if the steel bar differs by a grade, it can be replaced by a large diameter, if the steel bar differs by more than one grade, a transition section should be added.

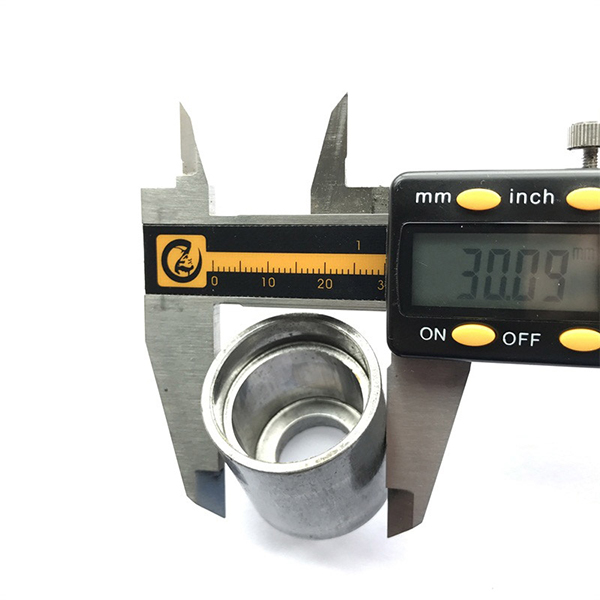

5, before extrusion connection work, must will mark on the bar end well (positioning, check mark), positioning marks its main purpose is to mark the steel reinforcement and the sleeve position, because the steel sleeve elongation after extrusion, positioning marks into the joint, so a check mark, can more easily check steel sleeve position is correct.

Product Display

Product detail pictures:

Related Product Guide:

We insist on offering high-quality production with great enterprise concept, honest product sales and also the finest and fast service. it will bring you not only the superior quality solution and huge profit, but the most significant should be to occupy the endless market for China Seamless Ss Tubing Manufacturers - High Quality Cold extrusion sleeve – Hengye , The product will supply to all over the world, such as: Italy, Paris, Jeddah, Customer's satisfaction is always our quest, creating value for customers is always our duty, a long term mutual-beneficial business relationship is what we are doing for. We are an absolutely reliable partner for yourself in China. Of course, other services, like consulting, can be offered too.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.